The Challenge:

How to cost effectively achieve assured destruction with zero impact on landfill?

A leading manufacturer of consumer products occasionally needs to dispose of off-spec or expired candles to ensure that these sub-par products do not end up being resold in the marketplace, thereby damaging the company’s reputation and disrupting brand integrity. However, they need to dispose of the product in alignment with their strict sustainability goal of sending zero manufacturing waste to landfill.

Traditional processing for product destruction—utilizing a compactor or shredder to render the product unusable—results in large quantities of waste going to landfill. So that was not an option.

The company was struggling to devise a method for separating the various components of the candles so that they could be recycled—in particular, how to completely remove the wax from the glass.

The Solution:

Devise a solution for separating the wax and glass, and source recycling options

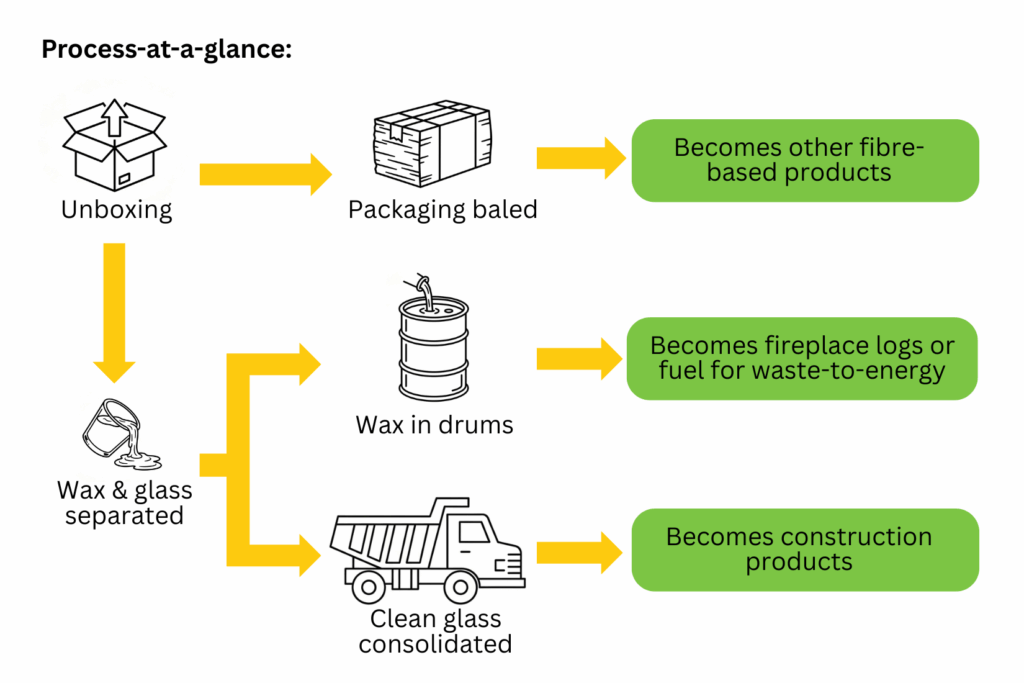

To ensure all individual components can be recycled, the various materials require separation and consolidation. Here’s how Aevitas does that:

- The candles are removed from the packaging, and the packaging is collected and baled for cardboard recycling.

- The solid wax is liquified and then the glass holders are rinsed, using an innovative approach developed by Aevitas engineers that removes 100% of the wax from the glass.

- The liquified wax is decanted into drums and the glass containers are consolidated, and these components are shipped to their respective recycling facilities.

All of this happens in a secured area at Aevitas to ensure client anonymity and guarantee assured destruction of 100% of product.

Aevitas sourced recycling options for the individual components to ensure 100% recycling of product:

- Cardboard packaging is used to make other fibre-based products.

- Glass is processed into lightweight granulate for use in construction products.

- Wax is used to make fireplace logs or utilized as fuel for waste-to-energy.

The Results:

Product destruction with no waste material going to landfill

Aevitas developed a cost-effective and sustainable solution to effectively destroy the excess product with zero impact on landfill.

This customer now trusts Aevitas for all of their assured destruction requirements.

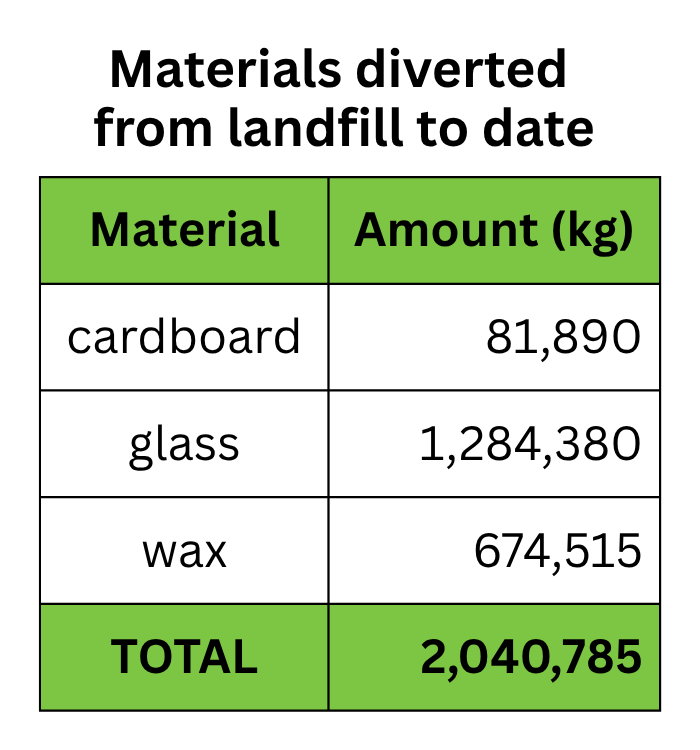

To date, over 10 years so far, Aevitas has helped this customer divert more than 2 million kilograms of material from landfill.

Contact Aevitas to explore the design of an assured destruction program to meet your needs.

Click here to download a PDF version of this fact sheet.

The manufacturer’s name has been withheld in accordance with our confidential assured product destruction program.